Solution for farmers, Household

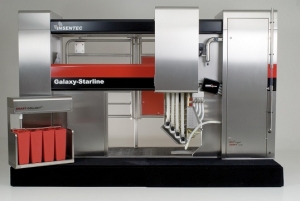

Insentec - Galaxy Starline AMS

Features of the Galaxy System

The past expectation of Automated milking focused mostly on life style and reduced labour for milking. The problem was soon evident that in exchange for a simpler and less labour intensive milking routine, the owner had to accept a complicated machine and increased overhead and operating maintenance costs. Insentec did not approve of that compromise!

By wisely avoiding the re-invention of the wheel, they built their new automated milking system along side an arm that was over engineered, extremely capable, very gentle when working around the animal and possessed a maintenance requirement of a six month lube. This arm had been utilized in much more demanding areas in hundreds of industries around the globe. They then carefully made certain that all this state-of-art equipment focused on the cow it was built to serve, to ensure her health and her milk’s top quality.

- A brilliant vision system that sees from the bottom-up. This simple design allows a whole new group of animals into the world of free choice milking. An industry exclusive!

- A unique preparation cup and routine that actually washes, drys and has a liner to allow a stimulating pre-milking under vacuum and with pulsation! An industry exclusive!

- A cleverly designed Teat cup unit positioned close to the udder reducing milk hose length, with it’s wash cover acting as a restraint for the animals rear leg.

- The Galaxy Liner is an impressive success in virtually eliminating liner slip, providing clean and quick painless milk harvesting. All of your cows will approve!!

Milking experience

The superior milking technique guarantees perfect milking and high capacity. A sound, thorough pre treatment is the basis for complete milking. Individual adjustments and attaching per quarter results in a smooth milking process without harming udder health. After the attachment of teat cups, each cow is post treated before leaving the milking system.

To ensure a positive first milking experience or assisting a nervous heifer, a manual control pad is conveniently located by the teat cup rack. This simple feature is an invaluable asset in the day to day reality of dairy farming. No animal needs to leave un-milked even during times of scheduled servicing.

Galaxy introduces SMART© (Starline Milk Acceptation and Registration Technology). The system applies innovative sensor technologies, which automatically separate milk with a certain amount of discoloration or flakes, including conductivity, milk flow measurement and vacuum sensors.

In addition to these key milk quality and udder health tools, the Galaxy system also offers real time wash monitoring with temp sensing and cleaning product measurements at the end of the milk transfer line. Any dangerous variances are brought to your attention.

SENSE© (SENsor Support Entry) is comprised of a flow sensor, vacuum sensor and conductivity sensor. SENSE is the standard term for all sensor applications which are used for measurements directly in the milking process. Information that can be trusted!!

In addition to these key milk quality and udder health tools, the Galaxy system also offers real time wash monitoring with temp sensing and cleaning product measurements at the end of the milk transfer line. Any dangerous variances are brought to your attention.

It also offers an easy to clean, pre-cooling tube cooler to quickly cool the milk before it makes it’s journey to the main storage tank.

SMART-COLLECT© automatically separates abnormal milk to 4 different units. After each separation, the separation line is cleaned with warm water.

The Prefabricated Galaxy Machinery Unit is another example of efficient design. Built to handle two stalls, multiple and redundant components are removed and therefore will never need to be serviced or replaced.

The MRS system records the individual activity of each animal at approximately 90 minute intervals and this information is sent to the central computer several times a day.

When combined with the Saturnus software, the MRS system provides the herd manager with clear management information and the attention lists shows which cows have increased or reduced activity. Using other important parameters from the cow calendar, the herd manager can determine the best moment for insemination. Using the same information from the cow calendar, the herd manager can treat cows with less activity.

The Saturnus© management program has been especially developed for robot milking and processes the newest sensor technologies. The software shows exactly how your animals and the system are functioning on clear displays with the latest data.

Saturnus monitors the milking process and automatically warns the operator if animals require extra attention or other special treatment. Alongside a robot milking system, Saturnus is a prime example of what an “exceptions” management software program can be.

Insentec introduces ProClean as an extension to the Galaxy-Starline milking system. The ProClean system consists of a highly effective cleaning of the teat cups with steam of 110 Deg. C in between each milking session. Research has shown that water hotter than 90°C will effectively kill 99% of bacteria.